The Power UMAC a motion computer with the latest hardware and software technology, providing the most high-performance, flexible machine controller in the world. The Power PMAC is a general-purpose embedded computer. It runs under a hard real-time Linux OS with a sophisticated motion and machine control application built in.

With the capability for a full operator interface, the Power PMAC eliminates the need for a separate PC. Users can also program in the easy-to-use Script language or the standard C language, leveraging its sophistication and flexibility.

Product benefits

Complete

flexibility

Full file

management system

Support for

large memory

Full 32/64-bit

architecture

Download the Power PMAC PDF for a detailed overview

Product features

Dynamic Multi-Block Lookahead

- Evaluates planned trajectory against motor limits

- Slows just enough to stay within position, velocity, acceleration limits

- Executes fastest possible traversal within machine constraints

Forward and Inverse Kinematics

- Simplifies programming for non- Cartesian mechanisms

- User routines convert between tool tip and actuator mechanisms

- Permits direct specification of tool tip path

S-curve Acceleration

- Automatically limits rate of change of acceleration (jerk)

- Specified by jerk magnitude or S-curve time

- Provides smooth profiles with reduced high-frequency content

Position Capture and Compare

- Specialised circuitry tying encoder counts to I/O

- I/O on exact count (w/sub-count interpolation) at any speed

- For probing, registration, measurement trigger, laser firing

Electronic Gearing and Cams

- Powerful master/slave techniques

- Position following (gearing) requires no program for motion

- External time base (cam) keeps full trajectory flexibility

Gantry Control with Skew Correction

- Multiple motors automatically slave commanded trajectory

- Automatic removal of power-on skew in homing search sequence

- Optional cross-coupling servo correction

Multiple Coordinate Systems

- Axes acting together should be in same Coordinate System

- Axes acting independently should be in separate Coordinate Systems

- Separate Coordinate Systems act as independent machines

Blended and Splined Moves

- Automatic on-the-fly transition for multiple programmed moves

- Controlled, specified, acceleration of transitions

- For single-axis profiles or multi-axis paths

Delta Tau’s Open Architecture Platform provides complete flexibility to choose multiple types of motors, feedback devices, encoders and fieldbuses so you can create a system perfect for your application.

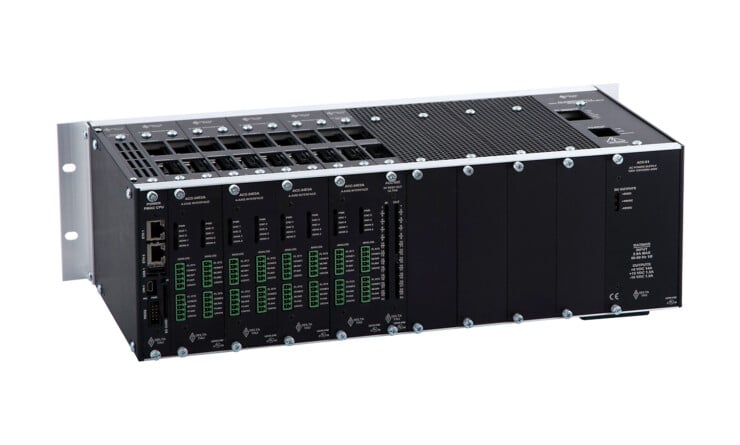

Additional axes, feedback, I/O and/or fieldbus interfacing is obtained by sliding accessory cards into the 3U rack system, available in 3 choices of rack widths (largest 21-slot version pictured below).

Up to 1.2 GHz Single/Dual Core

- Full real-time Operating System (Linux OS w/ real-time kernel)

- Full file management system (programs, data, files, etc.)

- Dedicated controller runs in the RT Linux environment

- Full 32/64-bit architecture

- Hardware 64-bit double precision floating point math

- Support for large memory

- 1GB or 2GB DDRAM active memory with error correction

- 64MB NOR flash for Kernel and Bootloader

- 512MB or 1/4/8 GB built-in NAND flash for user project (built-in)

- Interface for SD Card (SDHC, 32GB support

- Interface for USB 2.0 Devices (Hard drive, USB Stick, Keyboard, Mouse, etc.)

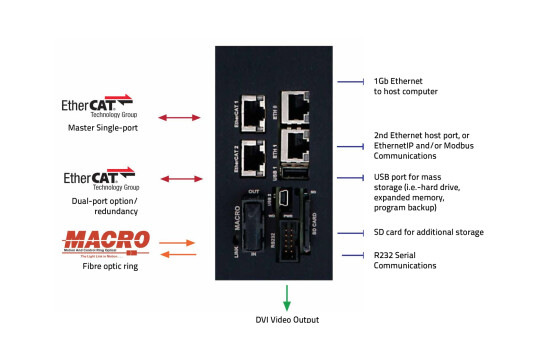

- 2 ethernet 1Gbps ports

- Built in USB2.0 Interface

- Optional 4x PCI Express (PCIe) port

- Optional Direct Video Interface (DVI Output)

- DVI output, 2 extra USB ports

Multiple Types of Communication Simultaneously